| Model Name | LA0733 |

| Cooling Mechanism | Air-Assisted Liquid Cooling, All Heat to Data Center Air (Sidecar) |

| Rack Size (W x D x H) | ORv3 Liquid Cooling Rack, 600mm x 1068mm x 2285mm |

| Cooling Capability | 80kW |

| Computing Node | Flexible (Depending on the Connected IT Rack) |

| Rack Deployment | Support Multiple Racks |

|

Cooling Kits |

|

| Redundancy | Fans (15+1), Pumps (2+1), and PSU (5+1) |

| Serviceability | Front-Access, Hot-swappable Fans, Pumps, PSUs |

| Management Control |

|

High Performance Liquid Cooling Solutions

Ingrasys offers a complete line of rack-level liquid cooling solutions based on where the heat is exhausted in the data center. These solutions include options for exhausting heat entirely into the data center air, into the facility water, or a combination of both. Whether your data center is traditionally air cooled or liquid cooled, Ingrasys delivers high performance cooling solutions that suit your needs.

Features

Higher Power Density

Great Cooling Capacity

Easy Serviceability

Management Control System

Liquid-to-Air Solution

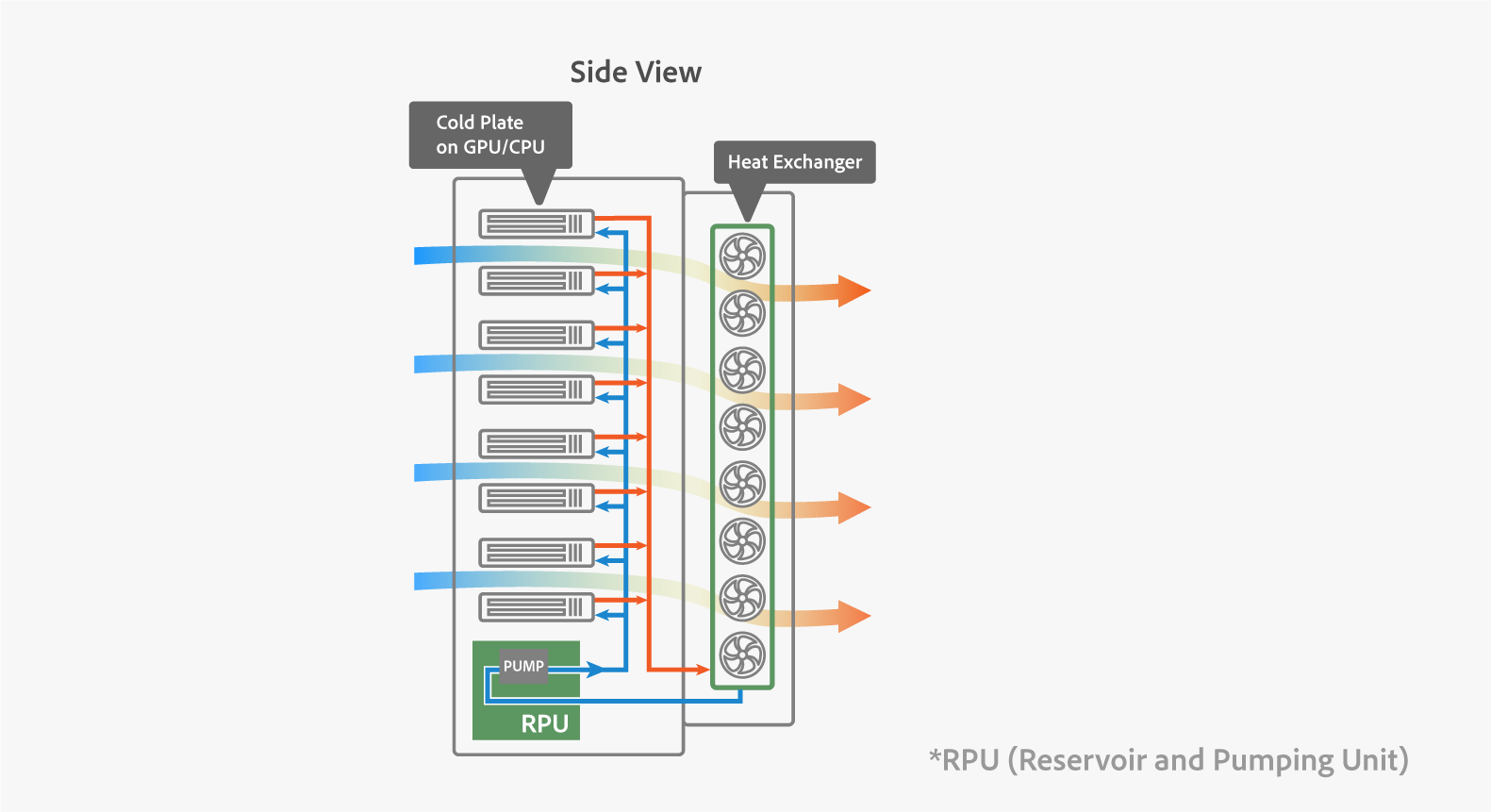

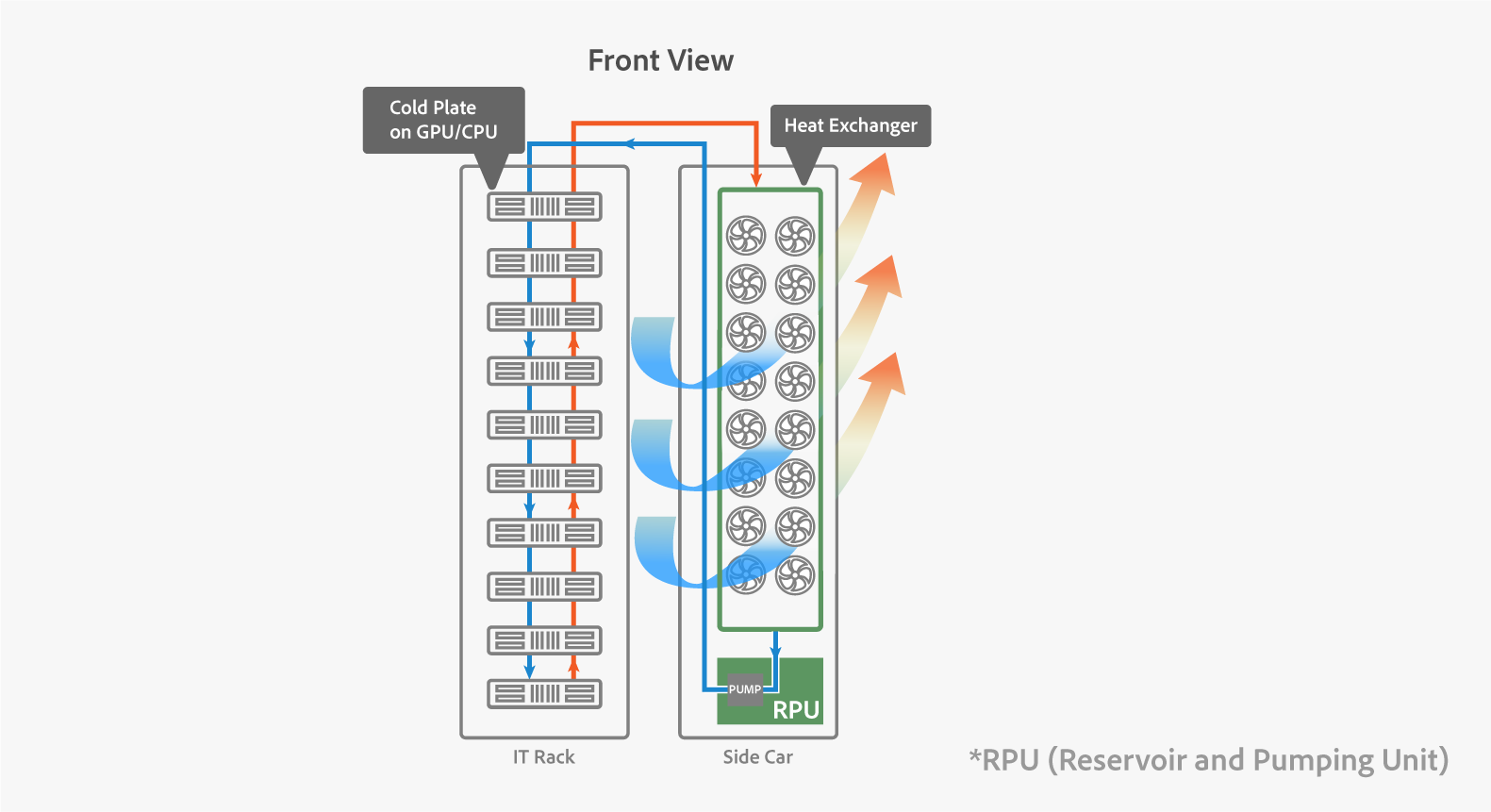

Scenario 1: In-Rack RPU with Rear Door Heat Exchanger

Scenario 2: Sidecar (Model: LA0733)

80kW Cooling Capacity

Deploy in connection with an IT Rack(s)

Specification

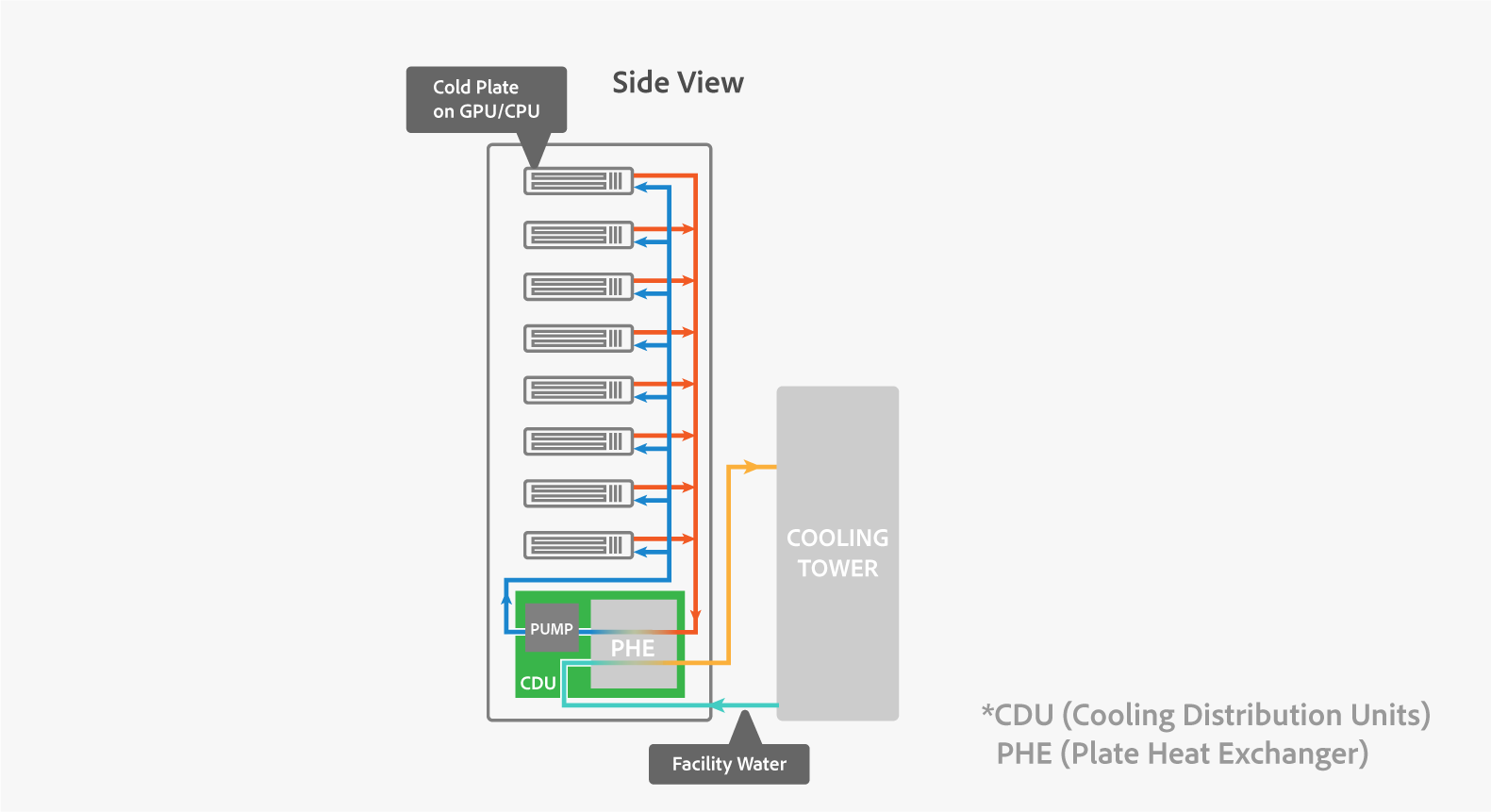

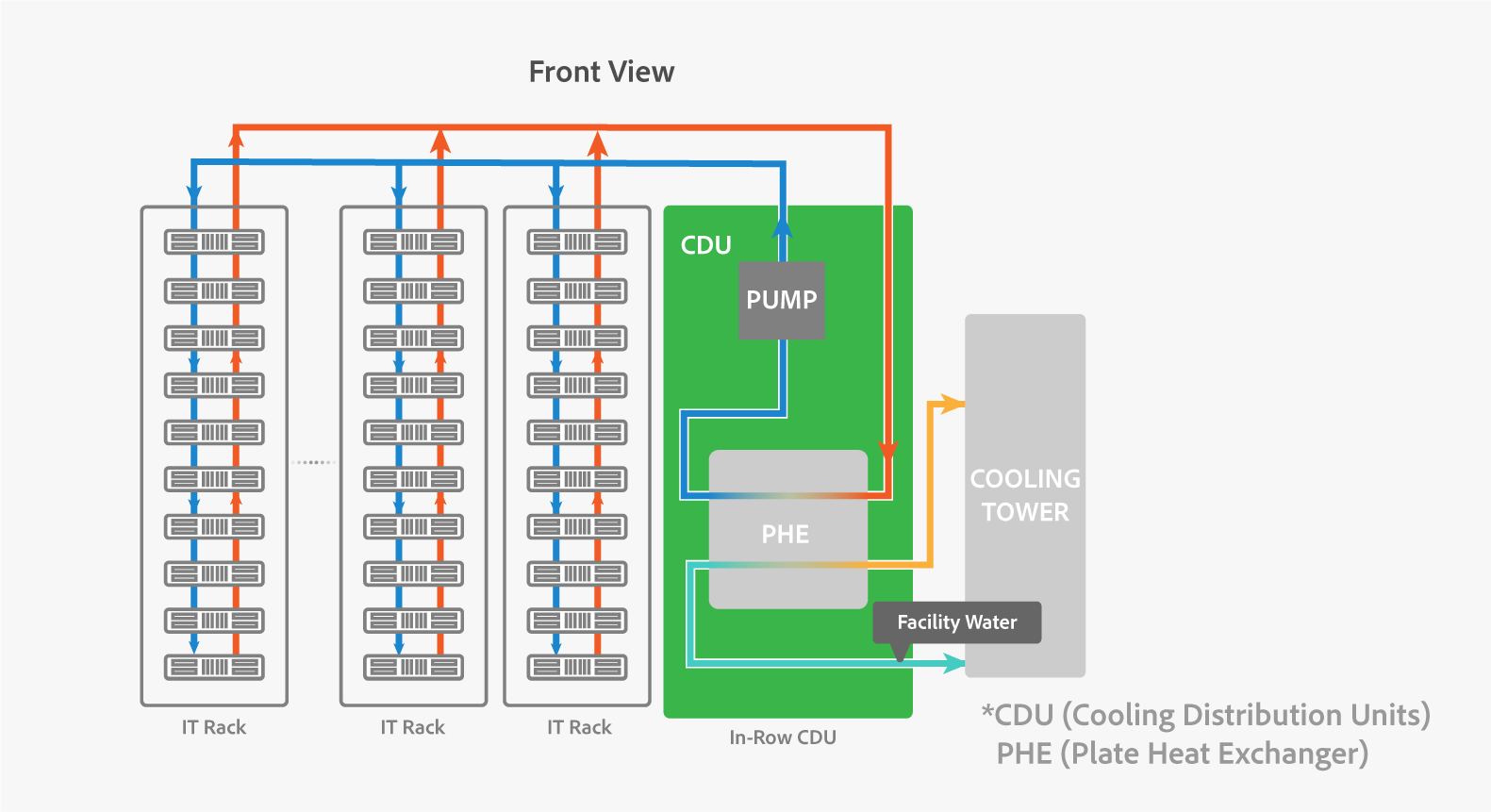

Liquid-to-Liquid Solution

Scenario 1: In-Rack CDU

Scenario 2: In-Row CDU

(Model: LL6003/LL13003/LL25003)

2500kW Cooling Capacity

Deploy in connection with an IT Rack(s)

Front Touch Panel for Easy Control

Specification

| Model Name | LL25003 |

| Cooling Mechanism | Liquid-to-Liquid, Main Heat to Facility Liquid |

| Rack Size (W x D x H) | 1200 x 1510 x 2256 mm |

| Cooling Capability | 2500kW |

| Rack Deployment | Support Multiple Racks |

|

Cooling Kits |

Plate Heat Exchanger |

| Redundancy | N+1 Redundant Pumps |

| Management Control |

|

600/1300kW Cooling Capacity

Deploy in connection with an IT Rack(s)

Front Touch Panel for Easy Control

| Model Name | LL6003/LL13003 |

| Cooling Mechanism | Liquid-to-Liquid, Main Heat to Facility Liquid |

| Rack Size (W x D x H) | LL6003: 800mm x 1200mm x 2100mm LL13003: 900mm x 1250mm x 2160mm |

| Cooling Capability | LL6003: 600kW LL13003: 1300kW |

| Rack Deployment | Support Multiple Racks |

|

Cooling Kits |

Plate Heat Exchanger |

| Redundancy | N+1 Redundant Pumps |

| Management Control |

|